Seed Cleaning / Oliver Gravity Tables

Oliver Gravity Tables (Gravity Separators)

Based in North America, Oliver Manufacturing has a long history of innovation and performance in agricultural processing. From inventing the gravity separator in 1897, to developing a three-fan design that tripled productivity in 1951, and launching the first fully automatic separators in 2011, Oliver has led major advancements in the industry. The company now operates globally, with much of its equipment still in use - some dating back to the 1950s. A fourth-generation, family-owned business, Oliver is preparing its fifth generation to carry on its values of innovation and customer support. Through in-house development and strategic partnerships, Oliver offers comprehensive agricultural hardware solutions, including its renowned gravity separators.

Gravity separators are a type of dry separation equipment. They can process a complex mixture of dry materials and separate the different individual particles depending on their density, resulting in a continuous gradation across a range of different densities. Gravity separators are also commonly referred to as fluidized-bed separators, air tables, and density separators.

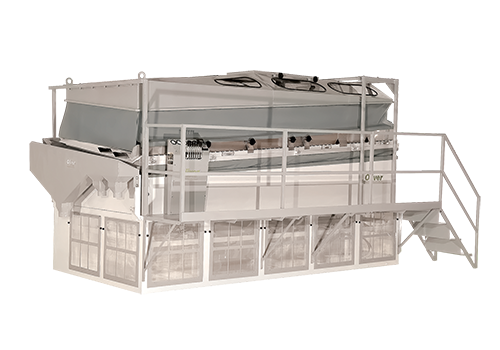

Maxi Cap Gravity Separator

The “big brother” of our Hi-Cap series separator delivers unexcelled cost efficiency on high volume installations where density separation, contaminant removal, and size separation are needed.

The Maxi-Cap high volume material separation machine removes heavier stone, glass, metal and sands as well as lighter lumber or agriculture products or plastics. Precise hydraulics and Opti-Drive automation make adjustment during operation a snap. Aspirating feeder removes the lightest contaminants as product is being introduced.

Maxi Cap Platinum Separator

One of the most advanced automated high-capacity separators on the market, the Maxi Cap Platinum adds one-touch power electronic control and repeatable memory to a proven separator platform, capable of separating up to 40,000 lbs of material an hour.

Instant power control of all parameters – fan speeds, table tilt, eccentric motion, and material feed rates – can be made through joystick and touchpad input or recalled from among up to 20 memorized setups.

Voyager Gravity Separator

Built on our legendary rugged chassis and components, the Voyager smart sorter offers an unparalleled number of adjustment points and power automation to simplify the purification setup with intelligent processing.

Programmable Logic Circuitry with a pre-loaded menu of up to 20 separation “recipes” means faster and simpler changeover between different products, our density separation equipment is for optimal separations from even the most minimally-trained operator no matter what your density separation, size separation or contaminant removal needs.

Laboratory Gravity Separator

The user-friendly Laboratory Compact Separator incorporates key features of larger Oliver machines for efficient, reliable results. It provides engineers with precise data to accurately predict outcomes in full-scale seed, nut, lumber, mining, and recycling operations.

Separate smaller samples of similar-sized materials (seed, grain, spices, herbs, mineral sands, and more) with outstanding efficiency. Integrating some of the best features of our full-size machines, Oliver’s Laboratory Gravity Separator achieves unsurpassed performance in concentrations of high value, low-volume samples. This is the only lab-sized separator durable enough for constant use in Oliver’s own R&D testing lab.

- Specialised machine and deck design for small lot processing up to 500lbs/hr

- Low noise

- User-friendly design

- Electronic control for the most precise fan and eccentric speed adjustment

- One year warranty

N-Series Gravity Separator

Our N-Series Hi-Cap Industrial Separator ushers in a new level of performance in heavy particle separation.

Our patented series fans produces uniform distribution of air through the deck with an improved air quality seal that reduces the potential for leakage. Control gates and under-deck diffuser ensure the correct air volume and improve the automatic separation of product.

A multiple throat deck design permits more precise machine adjustment and control, while the dust hood provides built-in feed and exhaust air controls. Large windows permit constant visual inspection of the product. This industrial separator also has easy machine adjustments (simple screw or clamp type) that allow you to have minimal workman training and supervision.

Oliver is a third-generation manufacturer in North America. Established in 1930 by Oliver W. Steele (who was born to one of the developers of the first modern gravity separator, circa 1897) the company has flourished throughout the past 90 years.

Let’s Talk

PMR can assist you with everything from cleaning & treating products,

gravity tables, debearders and screen cleaners, conveying & handling, silos &storage to complete plant design.

Give our sales team a call today and let us find a solution together.